CNC Milling Machine FF 500/CNC with Australian 4-axis controller

Shipping costs and GST (for Australian

customers) are calculated at checkout.

European-made CNC milling machine with 6 spindle speeds from 180 thru 2500rpm. Double roller bearings mount each of the recirculating ball screws on all three axes, driven by powerful stepper motors. Approximate machine travels are X 290mm, Y 100mm, Z 200mm.

The mechanical design is almost identical to our manual model 24320, carrying the same 400W condenser AC motor, cast iron dovetail X and Y ways with 5-screw gib adjustment, rotatable head and 6-way belt speed adjustment.

The sturdy vertical column has dovetail ways, 5-screw gib adjustment, sliding calibrated rule and telescopic leadscrew covers. Our new milling head can be rotated left or right up to 90 degrees, to a protractor scale. It includes a drilling quill, usable both vertical and when the head is rotated. An available fine feeder option allows accurate quill motion, beyond those of the hand lever. The quill may be clamped when not manually engaged.

The spindle nose is fitted with a Euro collet nut and we include collets 6mm 8mm 10mm 12mm. The vertical motion quill lever has a travel indicator thimble which may be zeroed at any point.

Our compound XY table of plane-milled steel has 3 full-length tee-slots 12 x 6 x 5mm and there is a second sliding, calibrated rule on the table's long axis. Model 24342 includes high-reliability AUSTRALIAN SUPPORTED 4-AXIS CONTROLLER.

Optional 4th axis UT 400/CNC is available.

By appointment, you may inspect the FF 500/CNC in our Tuggerah Business Park showroom.

Included components:

- Commissioning manual and safety instructions

- Collets 6, 8, 10, 12mm to Euro standard and collet nut

- Three hex keys

- Two spanners

- CNC milling machine with AUSTRALIAN SUPPORTED 4-axis controller for use with industry-standard CAD/CAM/CNC software. Our exchange service controllers promise fast recovery and high uptime.

- Illustrated workpiece, cutter and clamps ARE NOT INCLUDED

Technical specifications

- Single phase AC 220 - 240V @ 50 - 60Hz

- 400W condenser motor

- Spindle speed range 180rpm - 2500rpm by belt pulley position change

- Quill feed 30mm

- All ballscrews are 12mm diameter x 4mm pitch precision ground and pre-loaded

- Control of step motors: via AUSTRALIAN 4-axis CNC control unit (included in scope of delivery)

- Drive connection via parallel interface - connecting cable to PC included in scope of delivery

- Size of machine: table 400 x 125mm

Australian supported 4-axis control with advanced parameter supervision

Designed by high-reliability expert engineers, supported with fast exchange service

Connectors for XYZA, mains in, 2 switched outlets, computer plus ON/OFF and fuse access

All FF 500 models freely allow spindle head rotation +/- 90 degrees and beyond

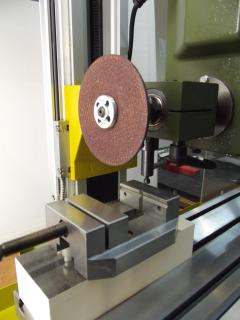

FF 500-series mill set as a surface grinder, 100mm wheel on our 44108 arbor

Related products:

All orders are subject to our terms and conditions of sale.